COLD PROFILING AND ACCESSORY PROCESSING

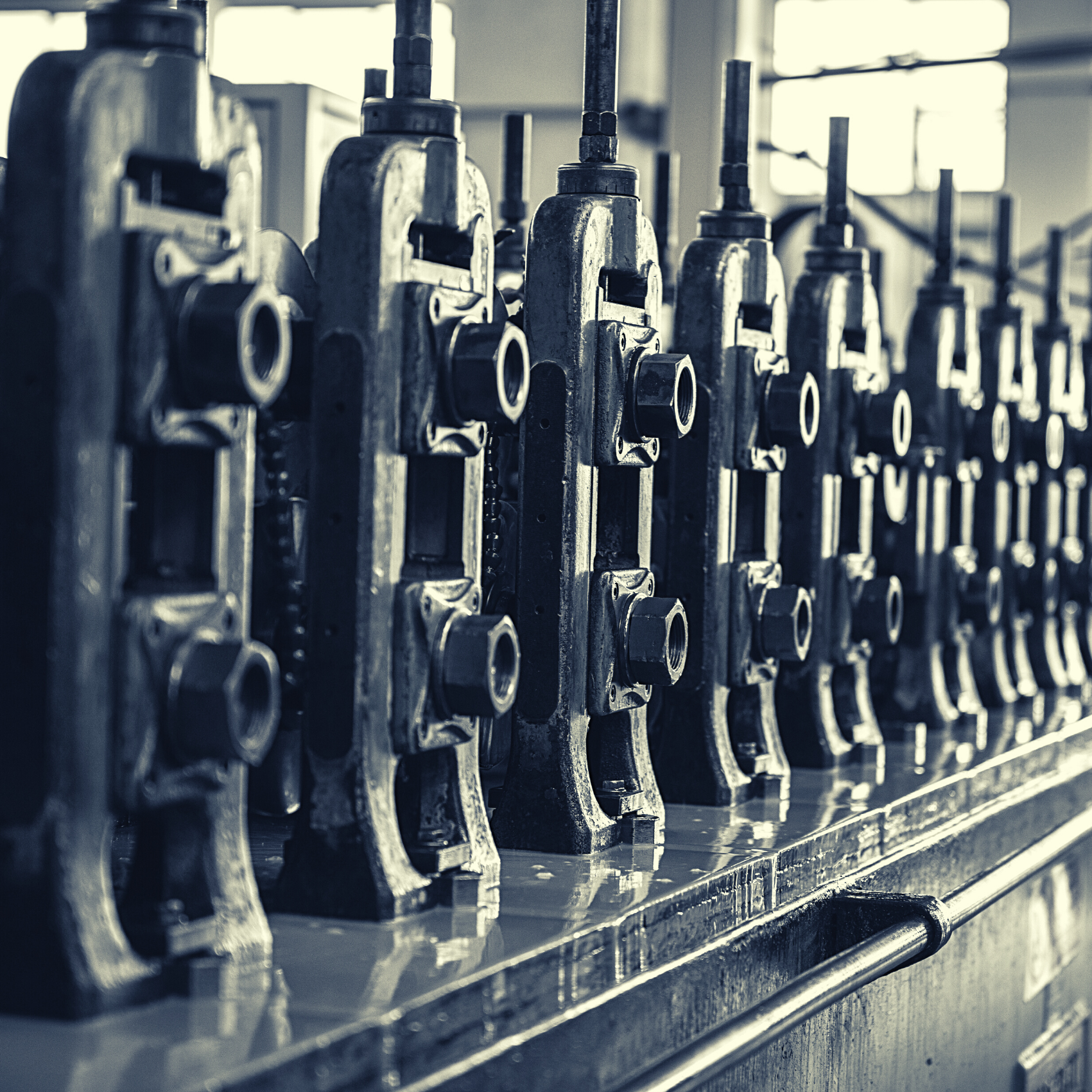

Damilano Group has 26 profiling lines for the creation of complex profiles, exclusively based on the customer’s design.

The roll forming machines are distributed over 14,000 covered square meters and transform about 1,000 tons of raw material per month with thicknesses ranging from 0.4 to 6 mm and coils widths that can be processed up to 850 mm.

COLD PROFILING

Cold profiling is a process of deformation of a sheet metal strip carried out at room temperature and continuously. Thanks to a series of multi-pass rollers it is possible to obtain profiles with different sections.

It is an efficient process for the production of profiles in large quantities, it allows, in fact, to significantly reduce processing times and costs, unlike the press-bending more suitable for the production of limited quantities.

Damilano Group has an internal workshop capable of designing and building all the necessary equipment such as: roller sets, blanking dies, accessories, cutting and recovery dies.

The profiling technology allows the execution of further processing directly on the production line and continuously.

Damilano Group performs the following processes in particular:

- Blanking

- HF welding

- Galvanizing on welding line

- Cut to size

Plus some other processes expressly agreed.

SHEARING

Drilling process using molds that is carried out in the machine during the profiling of the strip. The type of holes and their location on the belt is defined with the customer in the design and feasibility assessment phase.

HF WELDING

Process by which the sheet is joined at a certain point through a fusion process generated by the heat of high frequency energy.

GALVANIZING ON THE WELDING LINE

The zinc coating is applied continuously to protect the galvanized sheets from corrosion along the welding line. Processing on request.

CUT TO MEASURE

Obtaining special profiles often requires the supply of profiles cut to a defined length. Cutting to size can be performed either with a saw or with a cutting die.

OTHER WORKINGS

Upon completion of some projects, Damilano Group offers the possibility of carrying out further processing through:

PRESS-FOLDING

Press brake processing is not suitable for large quantities, Damilano Group uses this process only in exceptional cases.

Sometimes, following a technical-economic evaluation, it may be necessary to finish the execution of special profiles through this procedure in order not to excessively complicate the profiling equipment.

ROBOTIC WELDING

Damilano Group has two ABB robotic welding units for special processes requested by customers.